If the power fails ...

Venting and aerating batteries

A power failure does not have to be a disaster – stationary batteries are often used to provide an alternative source of power to electronic systems in such circumstances.

This keeps them going for a while, at least. Anyone using such batteries must, however, take special precautions, as described in EN 50272-2 (VDE 0510 Part 2) that was issued in December 2001.Systems that are subject to these precautions include safety lighting systems, emergency power systems and warning systems, i.e. burglary and fire alarm systems.

The protective aim of the mandatory precautions is to avoid hazards caused, for example, by electricity, leaking gas, or electrolyte. One precaution aimed at assuring this protection is the safe housing of the batteries in rooms. The standard defines rooms as:

- special rooms within buildings

- separate operations areas in electrical operating facilities

- cabinets or containers inside or outside buildings

- battery compartments in appliances, so-called combo cabinets

Erforderliche Lüftungsquerschnitte berechnen

A further protective aim of the standard is the avoidance of an explosive atmosphere, which can occur if hydrogen and oxygen are formed when charging batteries electrolytically. The aforementioned rooms therefore need to be effectively aired and vented, preferably by natural ventilation.

Effective means that the concentration of hydrogen in the ambient air must be less than 4% vol. The following formula can be used to calculate the necessary ventilation cross-sections of the air supply and extraction units for different types of batteries:

A = 28 • Q with Q ) 0,05 • n • Igas • CN • 10-3 [m3/h]

| n = | number of cells (e.g. a central power system comprising 18 blocks of 12V each = 108 cells) |

| Igas = | 1 (for sealed types, such as OGiV batteries, if not recharged more frequently than once a month in normal operation, and for safety lighting systems if generally recharged just once a year as part of the annual service) |

| CN = | battery capacity (Ah) |

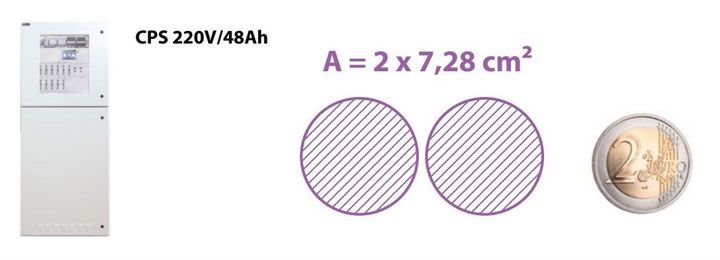

For example, therefore, a central power system with sealed 216V / 48Ah OGiV battery, the calculation would produce:

Q = 0,26m³/h

- Ventilation openings for air supply and extraction of A = 7.28cm²

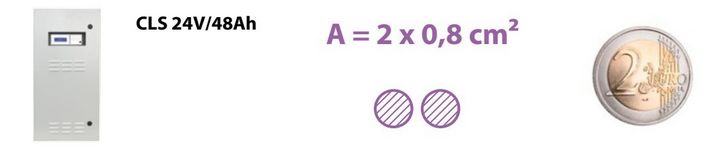

In the case of a decentralized emergency lighting system with 24V/48Ah battery, ventilation openings of just 0.8 cm² are required in each case for air supply and extraction, according to the formula.

Comparison of ventilation openings for a 216V/48Ah central power system and a decentralized CLS emergency lighting system with 24V/48Ah battery

Additional ventilation openings – yes or no?

When looking at the aforementioned ventilation openings, the question arises as to whether additional ventilation openings of max. 2 x 0.8 cm² in the room are really necessary, or technically feasible, from a technical and engineering perspective. The answer is no. In practice there is no such thing as a room that is so tightly sealed as to undercut the requirement for ventilation cross-sections. Assuming a door size of 2,000 x 700 mm and leakage of just 0.1 mm all around, the existing ventilation opening measures 5.4 cm². But only 2 x 0.8 cm² are required to assure the necessary air supply and extraction for the aforementioned 24V/48Ah battery. As such, compliance with a multiple of the minimum values is assured even with very minor leakage.

Observing the necessary room volume

A further factor that must be taken into consideration to avoid explosive atmospheres in ambient air is the requisite free air volume in the room/ area where the batteries are housed. Trade association regulation BGR 104 from December 2002 and technical rules for operational safety (Technische Regel für Betriebssicherheit) TRBS 2152 part 2 from March 2012 contain relevant information: The necessary free air volume is determined on the basis of an air exchange rate of 0.4–1 for rooms below ground level. This value is specified for the worst case scenario and is equivalent to a factor of 2.5 (1/0.4). Accordingly, the volume of the room in which the battery is housed must be larger than 2.5 times the volume of the appliance.

Conclusion: often, there is no need for special precautions.

When assessing the need for ventilation measures for batteries, always focus on evaluating the actual ambient conditions. Consider, for example, the free air volume in the room, or air leakage through doors and windows, etc.

When using decentralized emergency lighting systems with 24V batteries, especially, the structural conditions in practice by far exceed the aeration and ventilation requirements for batteries defined in the standards.

Additional, special ventilation precautions are therefore not necessary from a technical or engineering perspective and would not produce any enhancement in the compliance with the mandatory protective aim.

Sample calculation

A room with a volume (H x W x D)

Vroom = 2,50 m x 1,0 m x 1,0 m = 2.5 m³

houses a CLS Power 48 decentralized emergency lighting system (max. wattage appliance). The volume (H x W x D) of the appliance

Vappl = 0,8 m x 0,4 m x 0,19 m = 0.0608 m³.

The resulting free air volume is

Vfree = Vroom - Vappl = 2.43 m³.

which is equivalent to 39.9 times the volume of the appliance. Pursuant to TRBS 2152, 2.5 times the volume of the appliance would be sufficient – as such the room, which is itself very small, is still much bigger than necessary.

As these appliances are generally housed in much larger rooms or areas within fire sections, the safety level in practice is even higher.