Light for Kassel’s landmark

Bespoke solution for a Greek god

The Hercules monument is the most famous landmark of the German city of Kassel, in Hesse. Built between 1701 and 1717 to a design by the Italian Giovanni Francesco Guerniero, the impressive monument has been restored and renovated countless times over the centuries.

Hundreds of thousands of visitors from all over the world come every year to visit the edifice and enjoy its water features, which are active from May to October. The monument and the surrounding Bergpark have been a UNESCO World Heritage Site since 2013.

Now, for the first time, the landmark has been provided with an emergency lighting system – and therefore with more safety and comfort for visitors.

Project overview

| Subject: | Herkules, Kassel |

| Client: | Museumslandschaft Hessen Kassel (MHK) |

| Execution of 1st phase: | 2010–2012 |

| Further construction phases: | expected 2017 |

| Designer: | Dipl.-Ing. Oskar Winter, Kassel |

| Executions: | Elektro Brückmann, Kassel |

| INOTEC sales representative | Axel Schwedes |

| INOTEC products: | CPS 220 / 20 / 5,5 kW / 3A in special cabinet with humidistat-controlled heating (depending on the relative air humidity) |

From the highest point in a landscape of cascades, Hercules dominates Kassel’s Bergpark Wilhelmshöhe. The copper statue of the Greek demigod stands on the apex of a pyramid, which in turn stands on an octagonal building known as the Riesenschloss. Today the name “Hercules” refers not only to the statue but to the whole monument, which stands 70.5 metres high. The octagon is 32.65 metres high, the pyramid 29.60 metres and the figure of Hercules 8.25 metres.

Visitors arrive at the various levels via flights of winding stairs and are rewarded with fantastic views over the city of Kassel. The first construction phase in the recent work involved the development of the pyramid, which reaches right into the feet of the statue of Hercules. This required bridging a height difference of approx. 42 metres. The lighting will be extended during the renovation of the further levels over the next few years.

Our challenge: reconciling monument protection with technology

The new lighting design for the listed building presented a demanding task for all those involved: the lighting installation had to ensure that the unique architecture continued to be shown to best effect while still satisfying all the safety requirements. The objective of the safety lighting is to lead visitors safely outside in case of a power cut and consequent lighting failure.

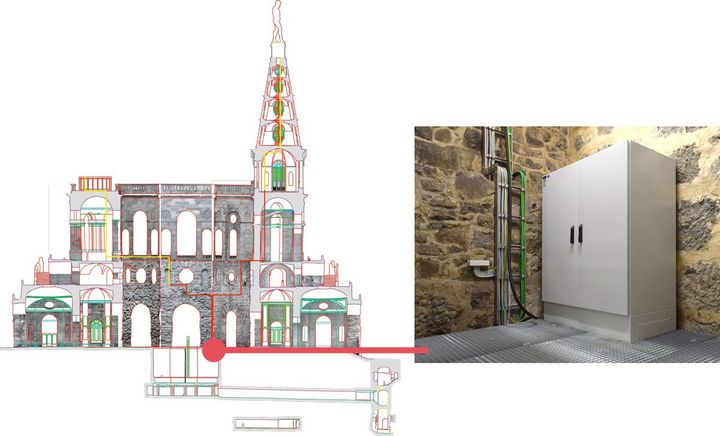

The system is based on a fire protection concept that takes into account the particular needs of a structure with only one escape route. Because the visitor route leads partly through unlit stairways, a special system was required. The structure formed a single fire compartment, as a result of which the electrical plant room could be combined with other electrical distributors. Only one room, narrow but with a high ceiling, on the ground floor of the octagon, was suitable for its location. So a second storey was built, with a narrow stairway. As a result, a tailored solution had to be developed to be able to transport the system into the room.

Solution: a made-to-measure safety lighting system

In close consultation with conservation officials, lighting designer Dipl.-Ing. Oskar Winter developed a lighting concept that can be both inconspicuously integrated into the architecture and, thanks to LED technology, economic to run. The INOTEC technology was planned by our sales representative Axel Schwedes and installed by Elektro Brückmann.

All the structure’s luminaires are connected to the safety lighting and made the technology easy to manage. Modified standard luminaires from third-party manufactures were used for the emergency lighting together with specially constructed bespoke luminaires. The unobtrusive SNP 1216 was used for the emergency exit luminaire, as it integrates inconspicuously into the monument’s architecture.

For the central power system, which supplies the monument’s modified standard luminaires and emergency exit luminaires with power in the event of a power failure, a special cabinet was constructed that could be split into two parts and transported through the narrow door into the room. Inside the IP54 stainless steel cabinet, a humidistat-controlled heating system ensures that the adverse climatic conditions in the cold, damp room, with high humidity levels, do not affect the central power system. This means that all the electronic components and batteries can be safely operated at all times. Sub-units in the vast building ensure the installation is economic.

The system has proved its worth after two years of operation with regular maintenance from Brückmann, the company that carried out the work.